ASIAN ORGANO INDUSTRIES

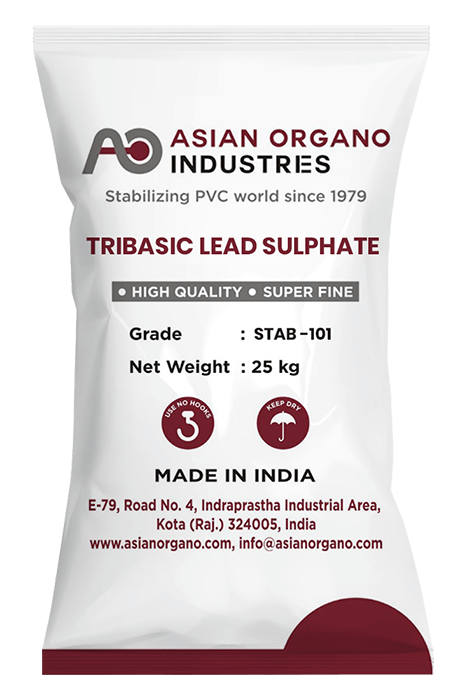

Tribasic Lead Sulphate

Tribasic Lead Sulphate (TBLS) is produced and supplied as a fine white powder. Tribasic Lead Sulphate can be heated to high temperatures without decomposition . It is suitable for all opaque compounds where long period heat stability is required, especially for rigid extrusion.

Applications

- Rigid PVC Pipes & Cables

- PVC Profiles & Flooring

- PVC Footwear

- Master Batches

- Profiles

- Sheet

- Compound for wires and cables

- Rubber

- Artificial leather

- Lead-acid batteries

Advantages

Due to its excellent thermal stability, it is particularly suitable for stabilising PVC which is to be processed at high temperatures or speeds. Good flow properties and ease of dispersion of TBLS are of considerable advantage in the preparation of PVC compounds TBLS has excellent stabilizing properties.

Grades

STAB-101, STAB-1011, STAB-1010

Dibasic Lead Phthalate

It is an excellent heat stabilizer, Particularly at temperatures, besides being also effective as a light stabilizer. It confers excellent long-term protection on phthalant plasticized PVC compound which is to be subjected to ageing at elevated temperatures,due to its low reactivity with plasticizers, the polyester type.

Applications

- PVC compounds

- Stabilizer Kicker for foamed PVC and the Stabilizer

- Pigment component in resin paste

- Cables covered

- Electric blankets

- Television Sets

Advantages

Excellent long term retention of physical properties and excellent electrical properties.

Excellent in long-term defence PVC compound which are using at elevated temperature PVC products maintain maximum physic properties in long life

Grades

STAB-105

Dibasic Lead Phosphite

Dibasic Lead Phosphite has been found to be a very economical heat & light stabilizer and antioxidant for PVC and hence extensively used in the manufacture of rigid PVC pipes, profiles and semi rigid irrigation hoses. It is recommended for use in rigid and semi rigid PVC applications along with lubricants such as Lead Stearate, Dibasic Lead Stearate.

Applications

- PVC Compounds

- Rigid PVC Pipes & Cables

- PVC Profiles & Flooring

- PVC Footwear

- Master Batches

Advantages

It protects PVC against degradation due to UV light and weathering.

Grades

STAB-106

Dibasic Lead Stearate

Di Basic Lead Stearate has a fairly low refractive index, and when used alone in P.V.C. has a low pigmenting value, producing a translucent product. It is suitable for both translucent and coloured compounds.

Applications

- PVC compounds (Plasticized PVC Compound)

- Cable Covering

- Rigid PVC applications

Advantages

It acts as a stabilizer lubricant, permitting increased rates of production by reducing friction.

Grades

STAB-102

Cadmium Stearate

Its primary uses are as a lubricant and heat stabilizer in plastics. It is manufactured by the reaction of cadmium chloride with sodium stearate. It is used as a lubricant and stabilizer in plastics, and as a commercial adherent.

Applications

- PVC Compounds

- Rigid PVC Pipes & Cables

- PVC Profiles & Flooring

- PVC Footwear

- Master Batches.

Advantages

Cadmium Stearate is a very good heat stabilizer & lubricant for transparent PVC Compound

Grades

STAB-110

Lead Stearate

A white powder that is used as a Drier in oil paints and varnishes to speed the polymerization and oxidation processes. Lead stearate is also used as a lubricant during extrusion, as a stabilizer in vinyl polymers and as a corrosion inhibitor in petroleum products.

Applications

- PVC Compounds

- Rigid PVC Pipes & Cables

- PVC Profiles & Flooring

- PVC Footwear

- Master Batches

- Grease & Lubricants

Advantages

Lubricant in PVC compound since it has only moderate heat stabilizer properties when used alone. It is used in conjunction with other stabilizers.

Grades

STAB-103

One Pack Stabilizers

Lead based One Pack Stabilizer is a combination of additives for the processing of PVC. A number of different additives like oxidizers, lubricants,impact modifiers, process aids, calcium stearate, and Lead stabilizers. etc are put together to form One Pack Heat Stabilizer Flake compound.

Applications

- Rigid Pipes

- Pressure & Non-Pressure Pipes

- Profiles

- Cables

- Reinforced suction hoses

- Sheets

- Tubings Conduits

- Suction pipes

- Casing & Capping

Advantages

Benefits of one – pack and lubricant packages are One ingredient replaces several others,

Improved accuracy of ingredient weights, Better reproductivity of compounding for problem free extrusion, Reduce inventory and Simplify inventory control.

One Pack Lead Stabilizers improves the heat stability of PVC during extrusion and also provide high output rates at lower costs. They find value in both single screw & in multi screw extrusion of pipe.

These are in form of flake chips which helps the PVC in the extrusion process.

Grades

STAB-310, STAB-320, STAB-330, STAB-340, STAB-300, STAB-400, STAB-500, STAB-600

Barium Stearate

Barium stearate is heat stabilizer and lubricant for transparent PVC Compound. It is generally used in conjunction with other stabilizers such as Cadmium Stearate and Lead Stearate. It can be used as a flatting and sanding agent in lacquers, coatings and inks and as a drying lubricant for rubbers.

Applications

- Footwear compounds

- Leather cloth

- Waterproofing agent

- Lubricant in metalworking

- Plastics, and rubber

- Wax compounding

- Preparation of greases

- Heat and light stabilizer in plastics

Advantages

It can be used as a flatting and sanding agent in lacquers, coatings and inks and as a drying lubricant for rubbers.

Grades

STAB-107

SUNGOLD

Zinc Oxide

ZnO is a white powder that is insoluble in water.Zinc oxide is an inorganic compound and is used as an additive in numerous materials and products.

Applications

- Products including cosmetics

- Food supplements

- Rubbers

- Plastics

- Ceramics

- Glass

- Cement

- Lubricants

- Paints

- Ointments

- Adhesives

- Sealants

- Pigments

- Foods

- Batteries

- Ferrites

- Fire retardants

- First-aid tapes

- Transparent electrodes in Liquid crystal displays

- Energy-saving or heat-protecting windows

- Electronics as thin-film transistors

- Light-emitting diodes

Advantages

Good transparency, high electron mobility, wide band gap, and strong room-temperature luminescence. harmless to humans with good bioactivity toward many microorganisms

Zinc oxide works as a sunscreen by reflecting and scattering UV radiation. Sunscreens reduce or prevent sunburn and premature aging of the skin.

Grades

WS

Zinc Stearate

It is a white solid that repels water. It is insoluble in polar solvents such as alcohol and ether but soluble in aromatic hydrocarbons (e.g., benzene) and chlorinated hydrocarbons when heated. It is the most powerful mold release agent among all metal soaps. It contains no electrolyte and has a hydrophobic effect.

Applications

- Plastics and rubber industry

- Polyurethane

- Polyester processing system

- Powder metallurgy

- In cosmetics

- Zinc stearate is a lubricant

- Thickening agent used to improve texture

Advantages

Zinc stearate is a lubricant and thickening to improve texture

It is often combined with zinc oxide. Zinc, on its own, is known to have antibacterial and antiviral properties.

Grades

COM, CHEM, SPL

Calcium Stearate

Calcium stearate is a carboxylate of calcium, classified as a calcium soap. It is a component of some lubricants, surfactants, as well as many foodstuffs. It is a white waxy powder.

Calcium stearate is recognized as physiologically safe, and is insoluble in most solvents. Compared to waxes, it has a relatively high softening point, and, consequently, does not become greasy at higher temperatures.

Applications

- PVC Compounds

- Rigid PVC Pipes and cables

- Leather Cloth

- Poly Propylene

- Explosives Plastic

- Master Batches

- Foundry Chemicals

- Cement Paints

- Cosmetics and Pharmaceuticals

- Rubber Tyre Tubes

- Hawaii Chappal

Advantages

In paper production, calcium stearate is used as a lubricant to provide good gloss, preventing dusting and fold cracking in paper and paperboard making. In plastics, it can act as an acid scavenger or neutralizer at concentrations up to 1000ppm, a lubricant and a release agent.

Grades

SPL, CHEM, COM

Aluminium Stearate

Aluminium stearate is a fine, bulky, odourless and colourless powder forming a plastic mass when heated, having the properties both of organic and inorganic matter. It embraces most of the characteristics of other metallic stearates and is regarded as the most important of these.

Applications

- Aluminum stearate forms gels with turpentine

- Mineral spirits, and oils

- It has been used as a Drier

- Thickener, Emulsifier

- Matting agent in paints and varnishes although excess amounts produce soft

- Noncohesive films

- Aluminum stearate is also used to waterproof

- Fabrics, ropes, Paper, Leather, Concrete, and Stucco

- It is used as an ingredient in photographic emulsions.

Advantages

The Stearate salts increase the thickness of the lipid (oil) portion of cosmetics and personal care products and reduce the clear or transparent appearance of finished products.Aluminum stearate is considered safe for general or specific, limited use in food.

Grades

NON-GEL, HI-GEL

Magnesium Stearate

Magnesium stearate is an additive that’s primarily used in medication capsules.It is a soap, consisting of salt containing two equivalents of stearate (the anion of stearic acid) and one magnesium cation (Mg2+). Magnesium stearate is a white, water-insoluble powder. Its applications exploit its softness, insolubility in many solvents, and low toxicity. It is used as a release agent and as a component or lubricant in the production of pharmaceuticals and cosmetics.

Applications

- Medical tablets

- Capsules and powders

- Pressed candies

Advantages

Lubricating properties, preventing ingredients from sticking to manufacturing equipment during the compression of chemical powders into solid tablets; magnesium stearate is the most commonly used lubricant for tablets Magnesium stearate can also be used efficiently in dry coating processes.

Grades

COM, CHEM, SPL

Glyceryl Monostearate

Glyceryl monostearate (GMS) is an effective emulsifier used in the baking industry available in the form of small beads, flakes, or powders. In addition to emulsification, GMS is a thickening agent and a stabilizer.

Applications

- Bakery

- Toffee & Choclates

- Pharmaceuticals

- Cosmetics

Advantages

In baking, it is used to improve dough quality and stabilize fat/protein emulsions.

Grades

SE/NSE

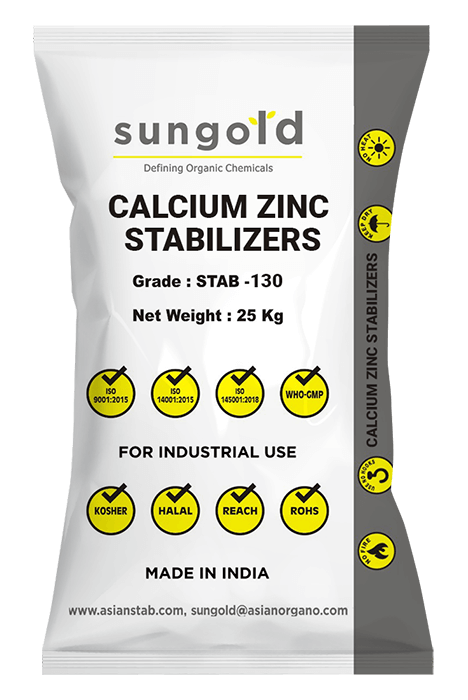

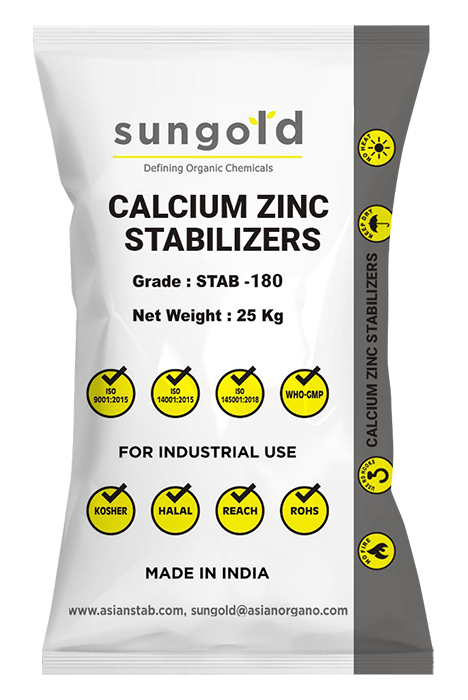

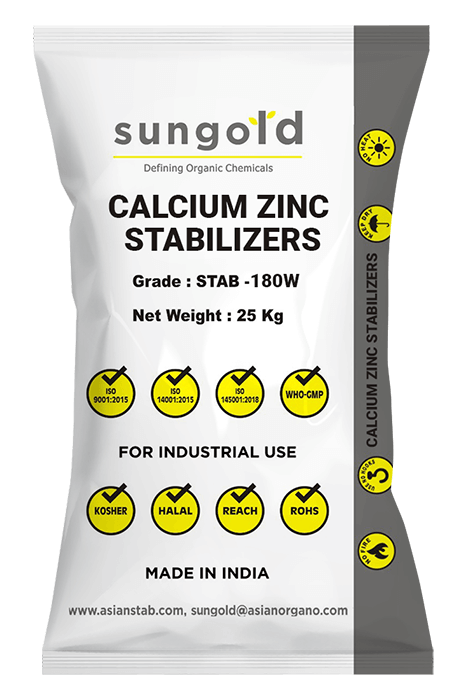

Calcium Zinc Stabilizer

The use of calcium/zinc stabilizers systems has been common in PVC applications for over 25 years.

These materials are generally based on metal carboxylates and will sometimes incorporate other elements to boost performance such as aluminium or magnesium.

Because the heat stability in some applications may require some enhancement when using calcium/zinc, organic co-stabilisers will also often be added to this type of formulation.

These materials include polyols, epoxidized soya bean oil, antioxidants and organic phosphites.

Applications

- Alcium/zinc

- Organic co-stabilisers

- Polyols

- Epoxidized soya bean oil

- Antioxidants and organic phosphites

Advantages

This type of stabilising system can give products which have a high degree of clarity, good mechanical and electrical properties, excellent organoleptic properties and good outdoor weatherability.

Grades

STAB70, STAB90, STAB130, STAB180, STAB180W

ZSL PRIVATE LIMITED

Lead Oxide

Litharge, which is Lead Mono-Oxide (PbO) is a yellowish or reddish, odorless, heavy, earthy, water-insoluble, solid, PbO

Applications

- Pottery

- Lead glass

- Paints

- Enamels

- Inks

- Lead Salts & Stabilizers

- Paints & Pigments

- PVC Compound

- Rubber Compound

- Lead Monoxide

- Lead Oxide

- Plumbous Oxide & Yellow oxide

- Lubricants and greases

- Insecticides

- Inorganic pigments

- Lead soaps

- Petroleum refining

- Rubber and PVC etc.

Grades

Litharge

Red Lead

Red Lead is a bright red to orange, red powder which is used in making Lead glass and red pigments.Red Lead is Lead tetra oxide,a water-insoluble compound that is prepared by the oxidation of metallic Lead or of litharge.Red Lead primer is one of the oldest and most commonly used anti-corrosion pigments applied to metal surfaces

Applications

- Intricate steel structures of buildings

- Ceramics

- Lead Acid Batteries

- Pigments

- Lead glass

- Fluorescent Tubes

- Heat Proof Glasses

- Optical Glasses

- Explosives Industries

Pure Lead

Pure Lead is produced from the refining operations done on remelted ingots produced from rotary furnaces. It is a pyro-metallugical process. The primary feed-stock is Lead Acid batteries. After melting in the rotary furnace, the lead metal is put into the refining kettles to produce high purity lead. Impurities including dross are removed and the molten Lead is cast using an automatic ingot casting machine.

Applications

- Lead Acid Battery

- Lead Sheet

- Lead Pipes

- Lead Wire

- Lead Oxides & Chemicals

- Pigments

- Lead Balls

- Cable Sheathing

- Ammunition

- Lead Weights

- Radiation Shielding

- Aerospace

- Ship Building

Advantages

Lead has the advantage of a very high density, low melting temperature and good malleability which enables lead articles to be cast, joined & shaped easily. It also has high electrical conductivity.

Lead Alloys

Any of the alloys for which lead is the base metal. The high-percentage group comprises lead alloys containing appreciable amounts of elements that increase the strength, hardness, and antifriction properties of lead and that lower the melting point of lead.

Different types of Lead Alloys:

Antimonial lead (lead, antimony)

Type metal (lead, tin, antimony) nt of lead

Applications

The primary use for lead alloys is in the production of battery parts for lead–acid batteries.

Advantages

It offers useful properties such as good corrosion resistance, malleability, energy absorption and electrical conductivity.